Introduction

Rotrex, a leader in custom winch solutions, took on a challenging project to design, manufacture, and install six custom-built winches for a historic bridge connecting freshwater River Fleet and saltwater Loch Fleet. In use since 1816, the bridge is an essential part of the local landscape and plays a crucial role in separating the two bodies of water. The winches ensure the efficient operation of 12 sluice gates, controlling water levels and maintaining the safe flow of the tide

Project Background

An exciting engineering feat. Rotrex constructed 6 custom-built winches for the historic bridge that connects freshwater River Fleet and saltwater Loch Fleet. Bear Scotland and Transport Scotland sought a solution to upgrade the sluice gate control system for the historic bridge. They tasked Rotrex with creating an electrically powered winch system that would fit seamlessly into the existing infrastructure and ensure the smooth operation of the sluice gates.

Client Requirements

The client’s main requirements for the winch system included:

- Six electrically powered winches that could be fitted onto existing base plates

- A pendant controller, control box, and a manual winch handle for emergency power failure

- Modifications to the housing to prevent vermin intrusion

- Compatibility with an automated monitoring system for water level control

Before the engineer could begin designing the winches they had to examine and inspect the location in which the winches would be placed. Rotrex load tested the base plates to ensure that they would support the weight of the new winches as part of the pre design inspection.

Innovative Design Solutions

Rotrex’s Project Engineer inspected the site and existing equipment to determine the best winch configuration. The A 55L EDL lifting winch was chosen, designed to allow for three winches to be fitted closely together. Additionally, a custom-designed window was developed to connect the winches to the sluice gates using chains, providing a secure view of the chains and sheaves while preventing animals from entering the housing unit.

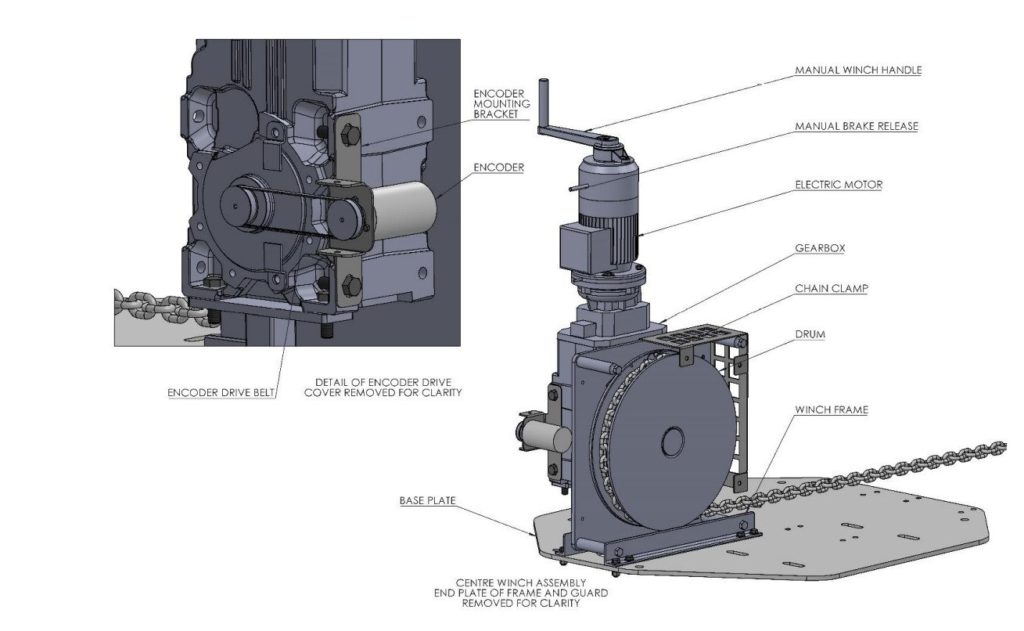

Key Components

- Manual Winch Handle

- Manual Brake Release

- Electric Motor

- Gearbox

- Encoder Drive Belt

- Encoder

- Drum

- Chains

- Drum Guard

- Winch Frame

- Control Panel

The Installation

Rotrex expertly installed the winches onto the base plate and connected them via chains to the sluice gates through a bespoke designed window. The window allows a secure view of the chains and sheaves while stopping animals from entering the housing unit. This automated monitoring system, supplied and installed by Datum Geotechnical and Structural Monitoring, monitors the water level and opens at low tide when the freshwater side rises above 900mm. With the incoming tide, the gates close and continue to open and close with the natural flow of the tide. The winches can be electrically overridden in case of emergency, but this is disabled at high tide to avoid damage from the high water pressure.

This is a technologically advanced, historically significant and environmentally friendly upgrade to an already impressive bridge that has stood for more than 100 years. A true testament to the skill and dedication of Rotrex and the teams involved in this exciting project.

Conclusion

Rotrex’s successful implementation of custom winch solutions for the historic bridge’s sluice gate control system highlights their engineering expertise and commitment to environmentally sustainable solutions. The technologically advanced upgrade to the bridge, standing for over 100 years, is a testament to the skill and dedication of Rotrex and the teams involved in this remarkable project.

The Mound Sluice Gate Winch System Includes:

- 6 x Electric Chain Winches

- 2 x Winch Control System

- 2 x Mounting Frame System

- Modifications to existing winch house